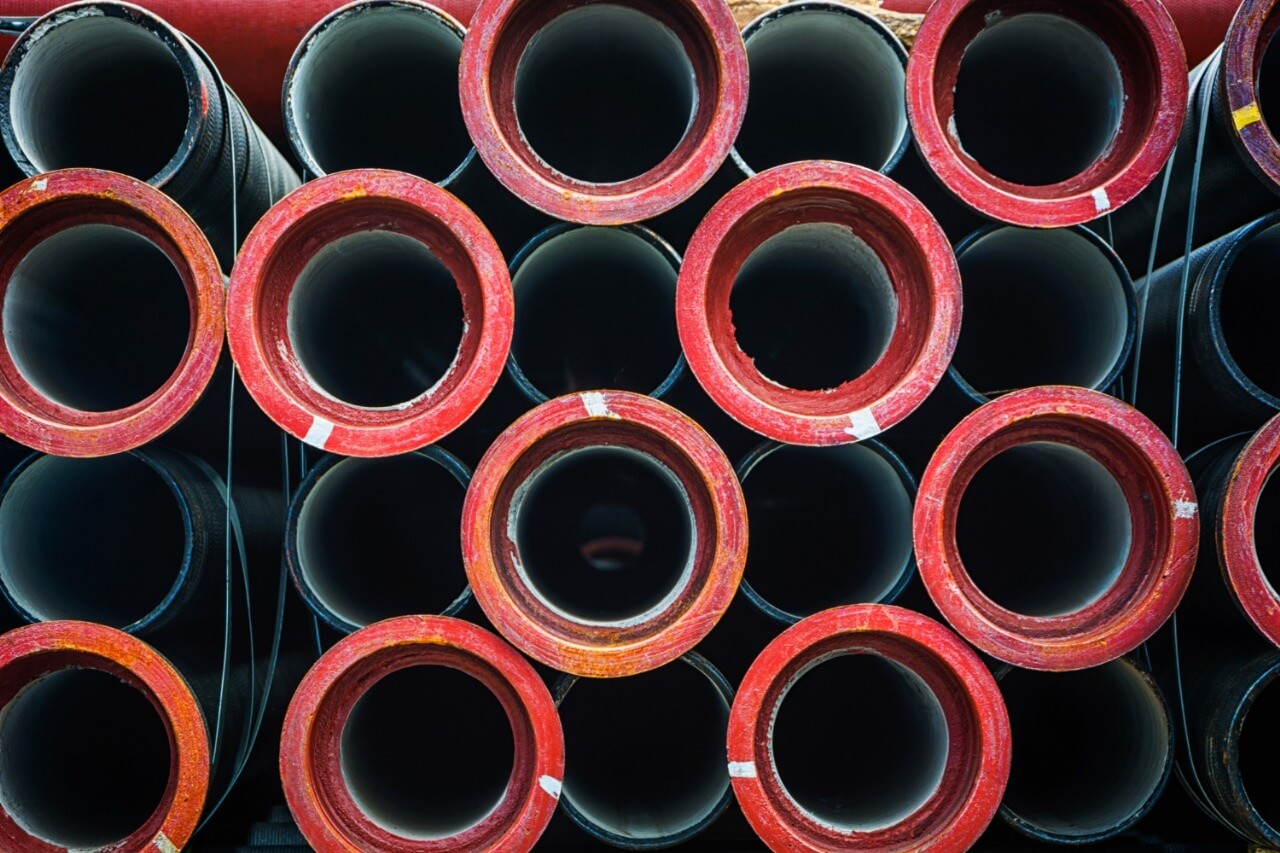

BOILER TUBES, SEAMLESS TUBES

Boiler tubes and seamless tubes are essential components in various industrial applications, notably in power plants, petrochemical industries, and manufacturing processes. Boiler tubes are specifically designed to withstand high pressure and temperature conditions, facilitating the transfer of heat from combustion gases to water, ultimately generating steam.

Seamless tubes, on the other hand, are manufactured without welded seams, offering superior strength, durability, and corrosion resistance, making them ideal for high-stress environments. These tubes are produced through a process of hot extrusion or cold drawing, ensuring uniformity and high quality. Both types of tubes are available in various materials such as carbon steel, stainless steel, and alloy steels, tailored to meet specific operational requirements, with seamless tubes often preferred for their high integrity and ability to handle extreme conditions.

APPLICATIONS

CONSTRUCTIONS

SCAFFOLDING, INTERIOR DESIGN, FIRE FIGHTING, WASTE WATER TREATMENT, ROOFING & GATE

Used in scaffolding, interior works, roofing, gates, fire fighting, and wastewater systems for durable and reliable support.

FARMS

(PLUMBING & FENCING)

Ideal for plumbing and fencing applications to ensure safe and efficient farm operations.

PACKAGING

PALLET MANUFACTURING

Perfect for pallet manufacturing to provide strong, stable, and secure packaging solutions.

STORAGE

RACKING IN SUPER MARKET

Suitable for creating racking systems in supermarkets and warehouses for organized and efficient storage.

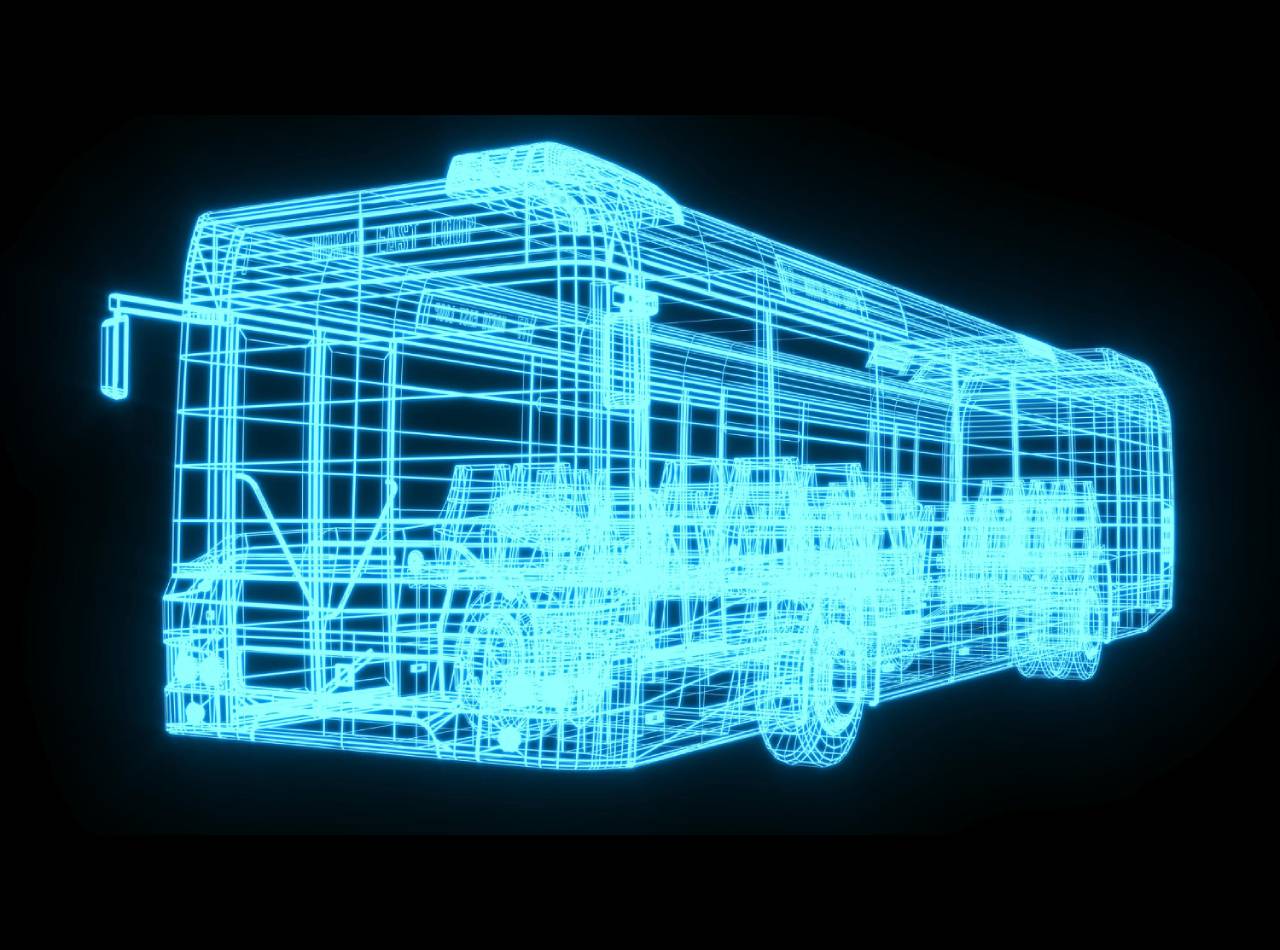

CYCLE, TWO WHEELER, FOUR WHEELER MANUFACTURING

Used in frame structures and components, ensuring strength and precision in vehicle production.

AUTOMOBILE LIKE BUS BODY BUILDING, TIPPER LORRIES

Applied in bus body building and tipper lorries for robust construction and long-lasting performance.

SIGN BOARDS

Used for creating sturdy and durable signboards suitable for both indoor and outdoor displays.